All final pieces have been created using Pantone colours from the Pantone solid colour book.

All my final pieces would be printed on cartridge paper because this is low cost and creates a good background to work with in order for the special finishes I would use to look their best. Initially I thought that because my campaign is a one off all my products would be best off being printed digitally but then I considered the fact that elements such as my advertising posters would be placed all over the world to really get my message out there and although the product is limited edition because its a world wide target audience the limit will actually not be that little due to the population of the world. I therefor think that lithography would be better because I can have quite a large number of each of the products printed and it will more than likely be cheaper to do so using this technique. The print job should also be quite low cost due to the few colours I have used in my designs and the areas this colour is applied to.

Paper bag printed on A1.

When the consumer purchases the iPod they would be given this bag to carry their product in. I decided to propose this layout as my final layout for my bag because I felt this was most successful out of all those that i'd designed so far and for me to move forward with this product I really need feedback before definitely choosing this design. The bag and packaging design will both be given very faint grey lines just before they are sent to print so I am still aware of where I need to cut and score but they aren't so visible that they ruin the design. Both the front and back iPod would be spot varnished so they stand off the cartridge paper and give a desirable high quality finish. The text on the bag would be foil blocked silver to again give a high quality finish and make the bag something that the consumer would consider keeping. This is one element of all of my products that may make the cost of the print job a bit more expensive because depending on which colour iPod the consumer has bought, the same colour will be applied to the bag, therefor there will be different colour batches needed to be printed resulting in different printing plates for each job. Once the bags are printed the correct die cut shape would be made for it and they would be die cut and scored within the screen for the handle and around the edge for a perfect finish ready to be made up by hand.

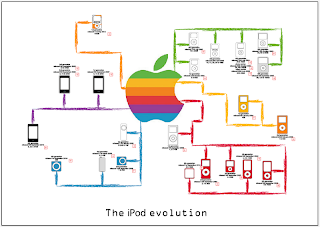

Evolution poster printed on A2.

This would come free with the purchase of every iPod in order to inform the consumer about how far the iPod has actually come. It would also be blown up to billboard size and be displayed on the stand at the Appleexpo because the fact the iPod is being launched to celebrate 10 years of iPod is significant. I thought A2 was an appropriate size for the evolution poster because all the information can be seen but is not too over whelming and is more likely to fit nicely within wall space if the consumer chose to display it. I chose to keep a bit of a white border around the edge of my design because this fits in with the layout of the other products I have created therefor keeping them as part of a series. The Apple and the different colour paths would be spot varnished in order to emphasise the fact the path has been the most important part of the evolution because if it wasn't for this there wouldn't have been generations of each iPod. The text to the bottom of the poster would be foil blocked for a high quality looking finish. These two small processes may add much value to the poster and make it seem like the consumer really has something worth keeping. This may be a slightly more costly product with the colour range being wider but colours are well worth the quality and the scale will effect the cost because if this is printed on sheets the likely hood is that you'll only be able to fit two to a sheet.

Packaging on A3.

When the consumer purchases the iPod this is the packaging it would come in. The final packaging design with added barcodes and information on the back has really come to life. I took the barcodes and symbols from the back of my own iPod packaging I had as an example of what it would look like if it was really made. I also copied the information from the back of my iPod packaging but to suit the particular characteristics of the iPod I have designed. I think the fact the packaging is so minimalist is one of the most effective things about it because consumers don't tend to appreciate being bombarded with information so it gives them enough but not too much and again links in with the rest of the product campaign. The screen of the iPod will be made from acetate so the product can be seen within the box, in a way teasing the consumer. The ipod image itself would be spot varnished to make it seem almost real, to make it stand off the page and also to give the packaging a high quality finish. The elements of information on the back would be left plain because the text is too small for a special finish and just needs to be legible. The text on the front of the packaging however would be foil blocked to link in with the other products I have already proposed. All these elements added together would give the packaging the 'limited edition' feel it should have so it again seems like something worth keeping. To end the design it would be die cut within the screen and around the edge from the printed page and then made up by hand. The great thing about this net is that because its so small you can fit quite a lot to a page therefor saving money. As with the bag, the colour of the iPod on the packaging would change depending on which colour iPod it is that the consumer purchased.

Bus stop advertisement - 1200mm x 1800mm.

This series of posters would be posted up in bus stops all over the world in order to make people aware of the product that is to come. Using bus stop advertising is probably quite significant because people who commute will see this and more often than not they carry some kind of mp3 player with them for their journey so i'd be attracting the correct audience. These were the three posters that I felt worked best together as a series because they are of the same nature in terms of layout so link together but they still look different. Due to these products being so big they would be printed from a roll rather than a sheet so to fit to the desired measurements. This is the one product in which I do not intend to use foil blocking on the text, this is because advertisements are generally up until the date of something has passed and then they are disposed of, so using such a high quality finish would be an expensive waste. I also think that using spot varnish would be a bit of a waste because this is definitely a finish that is meant to be interacted with and can not be enjoyed through a plastic sheet. This product would however have a matt varnish applied to it because I feel this will not look as cheap as just sticking with the cartridge paper and may bring the colours out in the design a bit more.This overall is going to be my cheapest product in terms of print finishes yet has to have the most impact in order for the campaign to work. I think the simplicity of the designs work really well because all the information that is relevant is there and if consumers want to find out more then they are able to by going on the website included. The fact the design is being printed on cartridge paper will benefit it in terms of colour because the colours tend to look quite bold on this particular stock. I could have considered printing this particular part of my campaign on glossy paper but again i'm not sure that this could fulfil its potential when placed behind a piece of plastic in a bus stop.

No comments:

Post a Comment